A benchtop passivation machine delivers high-performance parts cleaning, rinsing, passivation and drying, in a unit that fits on a tabletop.

All-in-One Benchtop Passivation Machine

All-in-one passivation systems offer the convenience and efficiency of combining the washing, rinsing, passivation and drying into a single, unified piece of equipment. The system houses heated cleaning solution, cascading rinse water, citric or nitric acid passivation solution, a second cascading rinse, and a final hot-air drying step.

Tank capacity ranges from 1.25 to 3.5 gallons, with custom sizing available. These systems feature four ultrasonic chambers, plus a hot-air parts dryer.

1.25-Gallon 386P Benchtop Ultrasonic Stainless Steel Passivation Machine

The Model 386P is a 5-quart stainless passivation machine that is designed for low volumes of small parts or for prototyping environments.

3.5-Gallon 782P Benchtop Ultrasonic Stainless Steel Passivation Equipment

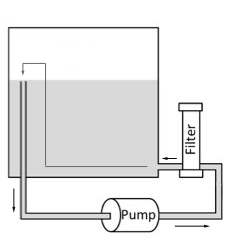

The Model 782P is a 3.5-gallon stainless passivation machine. Like the 386P, the process moves from left to right. Parts are cleaned, rinsed, passivated, rinsed, and then dried. The clean and passivation tanks can be optionally equipped with pump filter systems which provide 5-micron filtration of the cleaning and passivation solution.

Each tank has its own digital timer. Heater options include an internal or external mount for the thermostat, with temperature ranges from 85 – 180 °F.

The ultrasonic tanks use self-tuning ultrasonic generators that output square-wave sonic energy at a primary frequency of 38 kHz. (Higher-frequency 80 kHz ultrasonic generators are also available.)

The ultrasonic rinse system drives the drag-out chemistry to the surface of the rinse tank. Water flowing in from the bottom pushes the chemistry to an overflow weir, which drains through a standpipe.

Flowing Rinse for Benchtop Passivation Equipment

The hot-air dryer in a benchtop passivation system uses a combination of high heat and high air flow to dry parts. The thermostatically controlled temperature can be set between 140 – 180 °F.

Larger Tabletop Passivation Equipment

When you need larger tank capacity in a benchtop passivation system, look to Best Technology for multiple individual tanks. In systems like this, each process step (wash, rinse, passivate, etc.) is a separate tabletop tank. Combined together, 4 tabletop tanks and a standalone hot-air dryer form an effective passivation line.

Tank capacity for individual benchtop ultrasonic tanks ranges from 5 to 29 gallons per tank, with custom sizing available.

9-Gallon 188P Benchtop Ultrasonic Stainless Steel Passivation System

The Model 188P is a 9-gallon passivation line with 4 ultrasonic tanks and a hot-air dryer. This benchtop passivation system includes the following process steps:

- Ultrasonic Parts Cleaning

- Ultrasonic Rinsing

- Passivation

- Ultrasonic Rinsing

- Heated-Air Drying

Standalone Passivation Equipment

Our all-in-one ultrasonic passivation systems are also available as standalone console units. Check out our passivation wet benches to see our full range of integrated standalone passivation systems.

Ultrasonic Passivation Console

For greater convenience, our automated passivation equipment moves fluids rather than baskets of parts, freeing up the operator for other tasks. The operator simply puts in dirty, dry parts, hits start and returns to cleaned, passivated and dry parts.

Automated Passivation Equipment

Common Applications for Stainless Steel Passivation Equipment

- Medical device stainless steel parts cleaning and passivation

- Aerospace parts cleaning and passivation

- Nitric acid passivation type 2, 3, 4 per ASTM A967

- Citric acid passivation type 1, 2, 3, 4, & 5 per ASTM A967 using CitriSurf® citric acid passivation solution

- General washing and passivating for maintenance, manufacturing, rework and/or remanufacturing.

CitriSurf® is a registered trademark of Stellar Solutions, Inc. McHenry IL USA.

Common Configurations

We can easily make any bench top passivation tank size required for your application with little to no additional cost for custom size pricing. Below are a few common configurations for benchtop passivation machines.

| Model Series | Liquid Capacity (gallon) |

Inside Working Zones (l x w x h) |

| 386P | 1.25 | 9.5″ x 5.5″ x 6″ |

| 782P | 3.5 | 12″ x 10″ x 8″ |

| 499P | 5 | 15″ x 10″ x 8″ |

| 598P | 7.5 | 36″ x 8″ x 6″ |

| 188P | 9 | 18″ x 12″ x 10″ |

| 487P | 12 | 24″ x 12″ x 10″ |

| 300P | 15 | 24″ x 24″ x 6″ |

| 592P | 18 | 24″ x 14″ x 12″ |

| 1001P | 26 | 25″ x 18″ x 14″ |

| 801P | 29 | 36″ x 14″ x 14″ |

Start your benchtop passivation project now

Contact a passivation expert at Best Technology today to learn how you can bring passivation in-house with a benchtop passivation machine.