A passivation wet bench offers the advantage and efficiency of an all-in-one multi-tank system. Passivation wet benches can combine tanks for washing, rinsing, passivation and drying into a single, unified piece of equipment.

Smaller passivation wet benches are often called passivation consoles, while larger passivation wet benches are called passivation cabinets.

Passivation Consoles

Citric Passivation Console with Ultrasonic Cleaning

The Model E782-CP passivation console is a passivation wet bench that stands on the floor, in contrast to benchtop passivation systems. Instead of sitting on a separate table, the bench itself is part of the equipment design. This allows for plumbing and electrical connections in and out at one easy location, rather than wiring and plumbing each tank individually.

In addition, this model features lockable casters so that the unit can be transported to another manufacturing cell if necessary, and then relocked in place so it doesn’t move during use. Other features include pump-filter systems and digital controls for timers and temperature.

Typical tank sizes for this model are 3.5 gallons or 5 gallons, but custom tank sizes and configurations are available to suit the application.

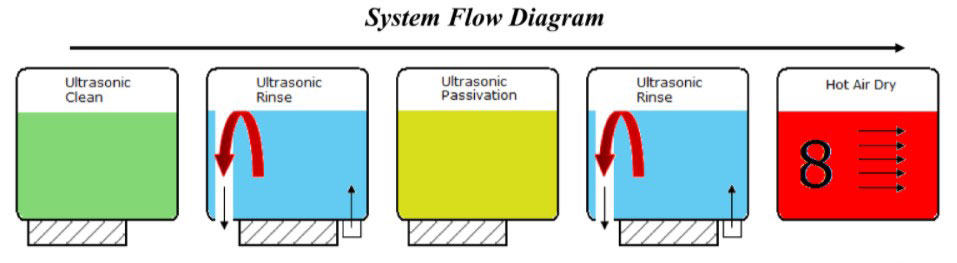

The passivation process takes place from left to right, with the following process steps as summarized in the diagram below.

- Ultrasonic clean – Heated alkaline cleaner

- Ultrasonic rinse – Cascading DI (deionized) water rinse

- Ultrasonic passivation – Heated citric acid

- Ultrasonic rinse – Cascading DI water rinse

- Hot-air dry

The left-to-right process orientation shown here is typical, but passivation wet benches can also be built for a right-to-left process flow if needed.

The left-to-right process orientation shown here is typical, but passivation wet benches can also be built for a right-to-left process flow if needed.

Citric Passivation Equipment Case Study

Many custom options are available for passivation wet benches, including PLC screens and data tracking. Check out the case study for this 6-station, 18-gallon citric acid passivation console that solved data tracking challenges for a medical device manufacturer.

Many custom options are available for passivation wet benches, including PLC screens and data tracking. Check out the case study for this 6-station, 18-gallon citric acid passivation console that solved data tracking challenges for a medical device manufacturer.

Passivation Cabinets

Nitric Passivation Cabinet with Ultrasonic Part Cleaning

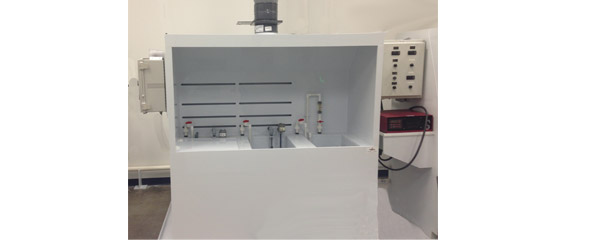

Larger passivation wet bench installations lose the advantage of portability, but gain the advantage of cabinet-style storage and additional options. This 11-station nitric acid passivation cabinet features an integrated in-tank cross-flow exhaust system.

Larger passivation wet bench installations lose the advantage of portability, but gain the advantage of cabinet-style storage and additional options. This 11-station nitric acid passivation cabinet features an integrated in-tank cross-flow exhaust system.

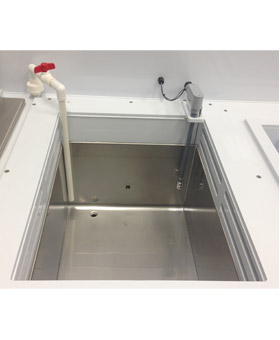

The system uses lip ventilation to create a channel that pulls nitric acid vapors from the tank solution surface. As a result the system can be operated as an open-top system rather than as an enclosed fume hood.

The following image shows an example of lip ventilation. The air channels along the top edge of the tank connect to an exhaust vent at the back of the tank. By connecting this vent to blowers and ventiliation, the fumes can be processed through facility exhaust, allowing operators to safely work with an open-top system that uses nitric acid.

Layout of this passivation cabinet includes ultrasonic wash, triple cascade counterflow rinse, passivation, rinse overflow and drying stations.

Unlike stainless-steel consoles, this passivation cabinet is constructed from polypropylene. Best Technology offers a full line of custom polypropylene passivation wet benches.

Passivation Fume Hoods

Passivation fume hoods are another type of wet bench, where the wet bench is enclosed for protection against hazardous chemical fumes. This type of passivation wet bench is most applicable with nitric acid passivation, which generates far more hazardous fumes than citric acid passivation. In particular, a fume hood is likely to be necessary when passivating with nitric acid and sodium dichromate or nitric acid at higher temperatures, as this generates more hazardous fumes, or when combining with another wet chemical process such as electropolishing or etching.

Nitric Acid Passivation Fume Hood with Electropolishing

The enclosed passivation wet bench shown above allows for post-clean processing, electropolishing, rinsing, nitric passivation, nitric acid neutralization, and a final rinse.

The enclosed passivation wet bench shown above allows for post-clean processing, electropolishing, rinsing, nitric passivation, nitric acid neutralization, and a final rinse.

Nitric Passivation Enclosed Chemical Fume Hood

This nitric passivation fume hood includes a cascade overflow rinse station, rear tank venting on two tanks, and top exhaust.

This nitric passivation fume hood includes a cascade overflow rinse station, rear tank venting on two tanks, and top exhaust.

Like passivation cabinets, passivation fume hoods are typically constructed from polypropylene. Other construction materials are available, depending on the chemical-handling properties required for application. Alternatives include:

- PVDF – Also known as Kynar®, or polyvinylidene fluoride or polyvinylidene difluoride

- CPVC – Also known as chlorinated PVC or PVC-C or chlorinated polyvinyl chloride

- PFTE – Also known as Teflon® or polytetrafluoroethylene

- PFA – Also known as perfluoroalkoxy alkane

- ECTFE – Also known as HALAR®, or ethylene chlorotrifluoroethylene

Need Automation?

Manual systems like the passivation wet benches on this page still require an operator to move baskets of parts from one tank to the next. For an automated alternative, please see our automated ultrasonic passivation equipment or automated passivation systems for high-volume production.

Common Applications for Passivation Wet Benches

- Industrial, aerospace and medical device stainless steel passivation per ASTM A967 with:

- Nitric acid passivation type 1, 2, 3, 4 with sodium dichromate

- Citric acid passivation type 1, 2, 3, 4, & 5 ASTM A967 using Stellar Solutions’ CitriSurf®

Common Configurations

Passivation consoles offer great flexibility in sizing. Below are a few common configurations for passivation consoles constructed with stainless steel. Other sizes can be customized based on the requirements of your application.

| Liquid Capacity per Tank (gallon) |

Inside Working Zones (l x w x h) |

| 3.5 | 12″ x 10″ x 8″ |

| 5 | 14″ x 9.5″ x 9″ |

| 9 | 18″ x 10″ x 12″ |

| 18 | 20″ x 12″ x 18″ |

Passivation cabinets and passivation fume hoods offer even more flexibility in sizing, as each is custom designed to fit the specific application. Built from highly-customizable materials such as polypropylene, our passivation cabinets and fume hoods can be depended on to meet your production needs.

All of our passivation wet benches ensure well-ventilated, repeatable passivation processes for industrial, medical device and aerospace stainless steel and titanium metal parts. Contact a passivation expert today to discuss your project and receive a free proposal.

CitriSurf® is a registered trademark of Stellar Solutions, Inc. McHenry IL USA