Dry electropolishing machines deliver a bright, shiny finish on delicate metal parts like medical implants, without the regulatory hassle involved with handling liquid electrolyte. Unlike traditional electropolishing, dry electropolishing uses porous, sponge-like, solid electrolyte beads to remove peaks of roughness from a metal surface.

Dry electropolishing machines are compatible with most industrial metals:

- Stainless steel

- Cobalt chrome

- Titanium

- Nitinol

- Nickel alloys

- Carbon steel

- Inconel

- Copper alloys

- Tool steel

- Tungsten carbide.

In addition, dry electropolishing machines are compatible with metals made from a variety of manufacturing processes, including:

- Cast metals

- CNC machining

- Swiss turning

- Additive manufacturing, also known as 3D printed metals. Compatibility includes both powder-bed systems and powder-fed systems such as:

- Direct Metal Laser Sintering (DMLS)

- Direct Metal Laser Melting (DMLM)

- Laser Powder Bed Fusion (LPBF)

- Selective Laser Sintering (SLS)

- Selective Laser Melting (SLM)

- Laser Cusing

- Electron Beam Melting (EBM)

- Laser Cladding

- Directed Energy Deposition

- Laser Metal Deposition

- Laser Engineered Net Shaping (LENS).

Dry electropolishing machines are particularly well-suited for applications with the following characteristics:

- Complete uniformity. Applications that require a specific RA value (roughness average) over an organic shape, like medical implants, work well with dry electropolishers.

- Highly detailed areas. Dry electropolishing preserves detailed lettering in metals, making applications with detailed lettering or numbers ideal for dry electropolishing machines.

- Sharp details. Sharp detail is not abraded away in the dry electropolishing process, so very sharp areas/edges such as those found in bone saws are well-suited for dry electropolishing equipment.

To learn more about the dry electropolishing process, please visit our page on "What is dry electropolishing? How dry electropolishing works."

Compact Series Dry Electropolishing Machines

The Compact Series dry electropolishing machines offer state-of-the-art surface finishing for high-value, complex and delicate metal medical parts such as implants. The primary distinction between each of the three models is the volume of the drum containing the electrolyte beads.

| Model | Drum Volume | Capacity (maximum volume centered to the axis) |

| 1H | 1.6 gallons (6 liters) | 3 in. diameter x 2 in. (75 mm diameter x 50 mm) |

| 10H | 2.4 gallons (9 liters) | 4.7 in. diameter x 2 in. (120 mm diameter x 50 mm) |

| 100H | 4.2 gallons (16 liters) | 7 in. diameter x 3.1 in (180 mm diameter x 80 mm) |

Compact Series dry electropolishing machines are ideal for additive manufactured parts, whether sintered (SLS or DMLS) or melted (SLM or DMLM), as well as for prototyping and short-run production.

Frequency Options for Dry Electropolishing Machines

Dry electropolishing machines are available in 3 different power supply/rectifier frequency options:

- LF – Low frequency only

- HF – High frequency only

- LF + HF – BOTH low frequency and high frequency

Use the following chart as a guide to determine which frequency option is right for your application. If your needs may change over time, it is best to go with the LF+HF frequency option for the greatest flexibility.

| Frequency | Materials |

| LF – Low Frequency | Stainless Steel Cobalt Chrome Nickel Copper Inconel Carbon Steel |

| HF – High Frequency | Titanium Nitinol Tool Steel Tungsten Carbide |

Dry Electropolishing Machine Controls

Compact Series dry electropolishing machines offer numerous controls for dialing in the best-performing settings, and then you can save up to 50 recipes for reuse. Some of these settings include:

- Metal type

- Electrolyte type

- Voltage

- Polarity

- Motor speed – Motor refers to the motor that rotates the fixture arm holding the parts in the electrolyte beads.

- Motor movement (Alternating, clockwise, counterclockwise)

- Vibration – Ensures homogeneous distribution of electrolyte beads.

- Humidity (Manual, auto).

Humidity is particularly important for dry electropolishing machines, as the amps of current applied to the metal parts are manipulated through precise control of the humidity level during processing. Every 2 minutes during a cycle, the machine takes a humidity reading. If the amps level is too low, the machine adds a small spray of deionized (DI) water from the system container to the electrolyte beads.

The addition of DI water occurs only in the first half of the cycle, since too much water can lead to a more aggressive surface finish treatment and reduce the shine. Reducing the water effect in the second half of the cycle brings out the shine in the surface finish.

Compact Series Dry Electropolishing Machine Specifications

| Model | 1H | 10H | 100H |

| Electrolyte Volume | 1.6 gal. (6 liters) | 2.4 gal. (9 liters) | 4.2 gal. (16 liters) |

| Capacity (maximum volume centered to the axis) | 3 in. diameter x 2 in. (75 mm diameter x 50 mm) |

4.7 in. diameter x 2 in. (120 mm diameter x 50 mm) |

7 in. diameter x 3.1 in (180 mm diameter x 80 mm) |

| Machine Dimensions | 20 x 45 x 27 in. (510 x 1150 x 690 mm) |

32 x 50 x 27 in. (820 x 1280 x 680 mm) |

37 x 56 x 29 in. (950 x 1410 x 730 mm) |

| Support Dimensions | 20 x 29 x 28 in. (505 x 743 x 702 mm) |

32 x 27 x 27 in. (820 x 680 x 680 mm) |

37 x 28 x 29 in. (950 x 700 x 740 mm) |

| Machine Weight | 212 lbs. (96 kg) | 383 lbs. (173.5 kg) | 480 lbs. (217.5 kg) |

| Support Weight | 104 lbs. (47 kg) | 192 lbs. (87 kg) | 220 lbs. (100 kg) |

| Power | 2 kW | 3 kW (single phase with industrial plug) |

5 kW (single phase with industrial plug) |

| Voltage | 220 V – 240 V | 220 V – 240 V | 220 V – 240 V |

| Air Pressure | – | 58-73 psi (air connector: 8 mm diameter or 1/4" BSP) |

58-73 psi (air connector: 8 mm diameter or 1/4" BSP) |

Fixture Options for Dry Electropolishing Machines

A variety of fixturing options are available with dry electropolishing machines. The ideal fixturing option can vary greatly from one application to the next. Some fixture options are suitable for holding one large piece, while others can hold several small parts like drill bits. For a sample of fixture options, please see the PDF document Dry Electropolishing Fixtures.

Test your parts for free

Receive a test sample of your metal parts electropolished for free!

We provide a detailed report, so you can be assured of process reproducibility.

Contact an electropolishing expert today.

Large Capacity Pro Series PRO500 Dry Electropolisher

The PRO500 dry electropolishing equipment offers much larger capacity than the Compact Series. While the Compact Series maximum capacity is 4.2 gallons (16 liters), the PRO500 delivers an impressive 69 gallons (260 liters) of electrolyte beads for processing per cycle.

PRO500 Electropolisher Key Features

Durability. Designed for durability and continuous operation in mass production, the system includes 3 mechanical movements on 8 spindles, and vibration on the drum and perimeter spindles for efficient process performance. The innovative power electronics use a pulse-generating power supply with the new silicon carbide-based SiC Pulser technology. The 8 independent high-frequency rectifiers are synchronized by optical fiber, delivering up to 360 amps and 35 kW.

Automation. The holder system with positive-pressure pneumatic connections reduces the loading and unloading times. At the end of each cycle, an airblade automatically removes electrolyte beads from workpieces, which helps recover electrolyte and avoid side effects like pitting on work pieces. The automated airblade takes the place of the manual post-processing rinse used in the Compact Series.

Data Logging. The Pro Series includes data logging for traceability of manufacturing processes. The data portal allows the user to monitor and track production and electrolyte status, update polishing programs, and update and track the maintenance schedule.

Versatility. The PRO500 system can output both high-frequency (HF) and low-frequency (LF) current, making it compatible with the broadest range of materials. In addition, the larger working volume permits a wider range of fixturing options and larger work pieces, up to 19.7 x 9.8 inches (500 x 250 mm).

Working Volumes for PRO500 Dry Electropolisher

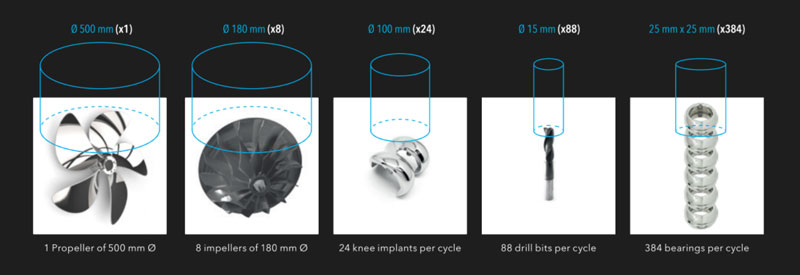

Working Volume Examples for PRO500 Dry Electropolisher

- 1 propeller, diameter 19.7 in. (500 mm)

- 8 impellers, diameter 7.1 in. (180 mm) each

- 24 knee implants per cycle

- 88 drill bits per cycle

- 384 bearings per cycle

PRO500 Dry Electropolishing Machine Specifications

| Technical Specification | PRO500 |

| Electrolyte Volume | 69 gal. (260 liters) |

| Capacity (maximum volume centered to the axis) |

29.5 x 9.8 in. (750 mm diameter x 250 mm) |

| Dimensions | 51 x 51 x 98 in. (1300 x 1300 x 2480 mm) |

| Weight | 907 lbs. (2000 kg) |

| Power | 35 kW |

| Frequency | 50 -60 Hz |

| Air Supply Pressure | 87-100 psi (Main air connector: 10 mm diameter, Holder air connector: 12 mm diameter) |

| Water Tank Capacity | 4.2 gal. (16 liters) |

| Water Tank Connector | 10 mm diameter |

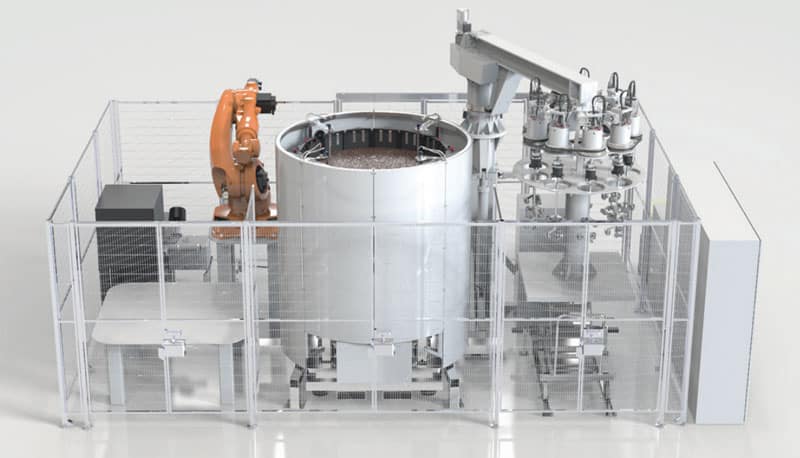

Large Capacity Dry Electropolishing Modular Solution for Mass Production

For even larger dry electropolishing production capacity, look to the Model 10000 Modular Solution. The electrolyte drum in this system offers a volume of 317 gallons (1200 liters), compared to the PRO500's drum volume of 69 gallons (260 liters). The modular system includes 3 options for working areas, all enclosed in a machinery guard system for worker safety:

- Electrolysis Workstation – Electrolyte drum and base

- Robot Zone – Solution for large workpieces and complex geometries, up to 29.5 x 19.7 x 19.7 inches (750 x 500 x 500 mm) for a single piece.

- Crane Zone – Solution for mass production, up to 2200 lbs. (1000 kg) maximum load.

The 10000 Modular Solution is highly customizable to production needs. For mass polishing of smaller items, the system can handle up to 200 pieces in a single cycle, with workpiece dimensions up to 2 x 2 x 2 inches (50 x 50 x 50 mm) each.

Electrolyte Drums for Dry Electropolishing Machines

Best Technology offers the following drum sizes of electrolyte beads for dry electropolishing machines.

| Product | Materials | Container Sizes Available | SDS |

| DRYLYTE – DLYTE- 01 | Standard electrolyte for most materials, except titanium alloys | 1.6 gal. (6 liters) 2.4 gallons (9 liters) 4.2 gal. (16 liters) 69 gal. (260 liters) |

SDS |

| DRYLYTE – DLYTE MIX MSA-S | Titanium-specific electrolyte for nitinol and other titanium alloys | 1.6 gal. (6 liters) 2.4 gallons (9 liters) 4.2 gal. (16 liters) 69 gal. (260 liters) |

SDS |

Common Applications

Dry electropolishing equipment is especially well-suited for high-value, delicate metal pieces that require precise surface finishing. Examples in the medical device industry include:

- Medical, orthopedic and dental implants

- Surgical instruments

- Stents

- Needles and cannulas

- Bone screws and plates

- Medical cutting tools

The ultra-smooth surface finish delivered by dry electropolishing also makes it an attractive solution for the aerospace industry, where smoother surfaces are critical for performance. Examples include:

- Parts made of tough, abrasion-resistant materials that require a smooth surface

- Rotating, aerodynamic parts such as propellers or impellers.

Eliminate layer lines. Additive manufacturing processes like direct metal laser sintering (DMLS) often leave layer lines that lead to low surface quality. These layer lines are also called the stair-stepping effect and can affect all additive manufacturing processes. Dry electropolishing removes layer lines and results in a shiny, smooth, high-quality surface finish.