Application

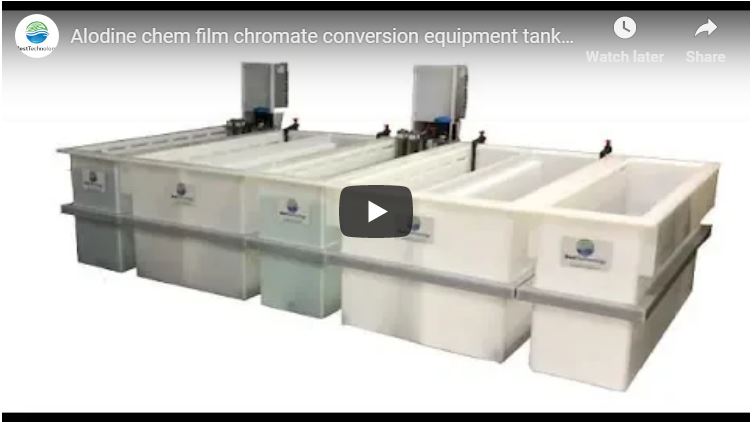

The Best Technology chromate conversion coating system allows for flexible manufacturing of many chem film and Alodine® needs. System can also be designed and built for both MIL-DTL-5541 Type 1 hexavalent chromium and Type 2 hexavalent chrome free processes. System tank configuration is dictated by Type 1 or 2 classification.

MIL-DTL-5541 Type 2 hexavalent chrome free equipment

This particular system for the aerospace industry is a hexavalent free, trivalent chrome line using TCP-HF (hex free) coating.

Type 2 Hex-Free chem film surface conversion process with TCP-HF, using Acid Clean process (typically 5 steps):

- Acid Clean – A general washing in a cleaning solution takes place as a pre-process step. This ensures that dirt, oil, and any residue formed from prior manufacturing or packaging processes is removed before the coating begins. Then a rinse and dry takes place.

- Rinse – cascade counterflowing – Ensure any detergents are removed from the part. A water-break-free test is often performed.

- Trivalent chromium, hex-free chrome coat – The surface conversion process takes place when the aluminum is immersed in the tank. The Alodine chromate coating gets applied immediately. The period of time that it remains in immersion varies based on the method of the application, the composition of the film, and the composition and size of the part itself.

- Rinse – cascade counterflowing

- Second Rinse is used in the type 2 method of surface conversion coating known as TCP-HF.

Video: Alodine Line for Hex-Free Chromate Conversion Coating

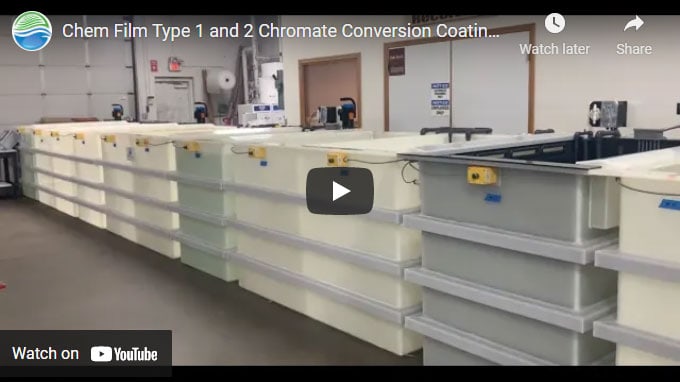

MIL-DTL-5541 Type 1 hexavalent chromium chromate conversion coating line

For MIL-DTL-5541 Type 1 hexavalent chromium lines, the Alodine chromate coating tank configuration is designed and built with typically 9 chem film tanks which are commonly at elevated temperatures.

Type 1 hex chrome conversion coating process (typically 9 steps):

- Clean – similar to Type 2 above

- Rinse

- Etch – If there are any areas that the chem film should not be applied to, the etching process covers those areas.

- Rinse – Ensure any etching chemistry is rinsed to stop the etching process.

- Deox – Deoxidation of the part occurs next, to remove any excess materials and oxides, contaminants and chemicals.

- Rinse – Remove any deox solution.

- Chem film coat

- Rinse

- Warm rinse.

Video: Chem Film Type 1 and Type 2 Chromate Conversion Coating System

Typical Chem Film Line and System Configurations (Custom Sizing Available)

Since each customer’s application is unique, the Alodine chromate and chem film Alodine coating equipment is designed specifically and to order. In general, tanks ranging from 12″ x 12″ x 12″ to 96″ x 144″ x 96″ can be built with various materials from metals, plastics, and polymers as well as hybrids. Based on chemicals used in the wash and chromate conversion coating system, various polymers are used for tank materials but most often polypropylene.

Chem film / Alodine Equipment

Chromate Conversion Line with Covered Tanks

The Type 2 chromate conversion coating system below features a containment stand that can contain spills or overflow up to 110% of the volume of the largest tank. This system also includes a suction system with pneumatic pumps for draining the tanks, and covers for each tank.

On this system, the process flow is right to left, instead of the typical left to right. Best Technology can build your chem film line with a process flow configuration that works best for your available space.

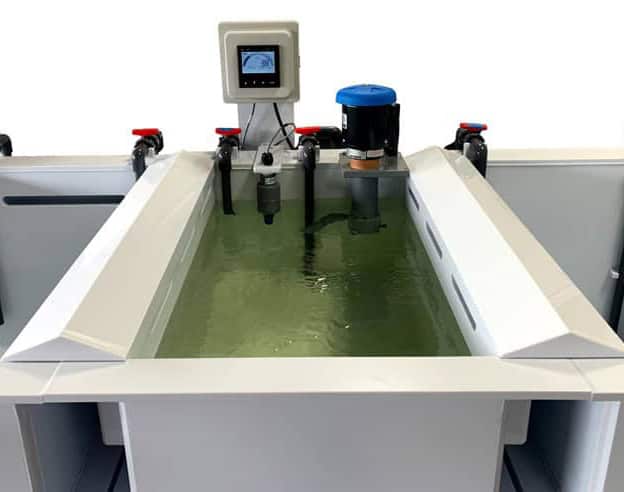

Chem Film Alodine Tank Line

The chem film tank on this Type 2 chem film line features drip diverters between each tank to help contain chemistry when moving baskets between tanks. The tank includes lip ventilation that allows connection of the system to customer-supplied facility exhaust for venting fumes for worker safety. The system also features a pH meter and circulation pump.

Type 2 Chem Film Line with DI Skids

The Type 2 chem film line shown below includes three DI skids for using deionized water (DI water) with the system. A DI water rinse provides the highest level of quality for precision cleaning and rinsing applications.

Chem Film Salt Fog & Humidity Test Chambers

Salt fog and humidity test chambers simulate harsh environmental conditions to test material and process reliability. These chambers can replicate marine environments with salt fog, high humidity conditions, and even the salinity of the human body to test medical implants.

Best Technology has the experience and the resources to build chromate conversion coating systems for Alodine / chem film applications both large and small. Let our application engineers design an Alodine line for your products. Contact us to learn more and start your project today!